The Coupled Roof, Ceilings and Trusses

Moving off from early roof forms that provided each wall and roof in one unit, succeeding development showed a real roof designed on masonry or timber walls. the only type of roof was a coupled roof, consisting of 2 lengths of timber bearing against one another at the highest and resting on a plate at their feet. The timbers, known as couples, were pegged along at the highest with timber dowels and were equally pegged or spiked to the plate.

The term ‘couple’ was used until the fifteenth century once the terms ‘spar’ or ‘rafter’ began to be used. The term rafter in fact continues to be wont to describe the piece of timber during a roof spanning from the ridge to the place. paced regarding four hundred millimeters apart tied solely by horizontal binders and tile battens. the easy couple was adequate for tiny span dwellings and steep pitches, however the outward poke force at the feet of the rafters caused stability issues with the walls, and overly long rafters sagged within the middle beneath the load of the roof covering. The illustration in Fig: one.1 shows the specified form in solid line and also the deflected form in line.

To overcome each of those issues the ‘wind beam’ or ‘collar’ was introduced. whether or not the collar acts as a tie or a strut for the couples can depend on the stiffness of the supporting wall below. presumptuous but, that the wall is therefore substantial that it'll not be pushed outward by all-time low section of the couples, then the collar can act as a strut. If however, as is a lot of probably with early timber-framed buildings, the wall is comparatively versatile then in this case the collar would act as a tie holding the couples along.

There would still be some outward thrust however this might be restricted by the collar to the degree of bending within the lower a part of the couple solely. It will without delay be appreciated that in larger roofs, wherever the walls square measure comparatively versatile, there's a substantial fastening result within the collar demanding a lot of refined joint between collar and couple than may be achieved with easy iron nails. The collar was thus ofttimes articulate to the couple with a halved dovetail formed joint, typically secured with hardwood pegs.

|

| Fig: 1.1 Simple Coupled rafter |

STABILITY

The next development was to suit further members to help with the soundness of the roof in windy conditions and these were known as ‘sous-laces’ or braces. On roofs made on substantial masonry walls that were conjointly terribly thick, any struts or ‘ashlars’ were introduced to stiffen the lower section of the couple. Fig: 1.2 illustrates this kind of construction, the plate being well-fastened to the wall with an all-time low member of the stone halved over it to stop the roof slippery on the highest of the wall.

These currently terribly substantial ‘couples’ began to be spaced more apart and have become called‘principals’. Between these main members, easy couples or ‘rafters’ were placed, however, to avoid sag or to accommodate longer rafter length presumably not on the market in one length of timber, associate intermediate support was required and this was known as a ‘purlin’. The purlin is successively supported by the principal couples, as shown in Fig: one.3.

|

| Fig: 1.2 Ashlar stiffening |

|

| Fig: 1.3 Principal trusses and purlin roof |

|

| Fig: 1.4 Tie beam truss |

The tendency for the roof to unfold was currently focused within the heavily loaded principals and it became apparent that if spans were to extend this spreading would be controlled. The ‘tie beam’ was introduced therefore forming the primary ‘trussed’ or ‘tied’ roof. Fig: 1.4 illustrates the roof type delineated.

As development progressed the span of the roof was restricted solely to the supply of long timbers used for the tie, however, it's obvious that these long beams themselves would tend to sag below their own weight. to stop this happening they too had to be supported and this was through with the introduction of ‘struts’ fitted to a corbel engineered into the wall below, as illustrated in Fig: one.5.

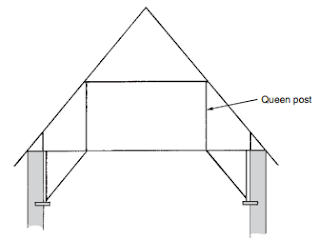

With this beam currently changing into significant support, a special configuration of members evolved changing into additional just like the truss common nowadays. Having stiffened the beam it became apparent that this might be used as a significant structural item from that to support the principals. the key support running from the middle of the beam to the ridge purlin was called the ‘mountant’, currently cited as a ‘king post’ (see Fig: one.6). A post truss is additionally illustrated in Fig. 9.1, getting used as a part of the structure of associate degree attic space. With 2 posts introduced the roof form is thought as a ‘queen-post’ truss, that in its simplest type is shown in Fig: one.7.

This explicit roof type gave the chance of providing a restricted room inside the roof. It ought to be remembered that till this stage of development all roof forms and trusses delineate had no ceiling and were hospitable the side of the rafters and roof covering. To use the post roof types associate degree attic, a floor was required therefore making a ceiling for space below.

|

| Fig: 1.5 Strutted tie beam |

|

| Fig: 1.6 King post truss |

|

| Fig: 1.7 Queen post truss |

CEILINGS

Ceilings were first referred to in descriptions of roofs in the fifteenth century when they were known as ‘bastard roofs’ or ‘false roofs’ and then later as ‘ceiled roofs’, hence ‘ceiling’ as we know it today.

The ceiling supports were known as joists or cross beams again being supported by the hard-working tie beam between the principals. The construction is illustrated in Fig. 9.2.

Continuing developments of the roof form itself and demand for even larger spans and heavier load resulted in some relatively complex principals or trusses being developed. One such form was the ‘hammer-beam’ roof, illustrated in Fig: 1.8. Clearly, this is not a roof to be ‘ceiled’, being very ornate as well as functional.

|

| Fig: 1.8 Hammer beam truss |

The hammer-beam roof is usually to be found supporting the roof over halls in massive mansions and in fact churches. The roof was framed in such a way on the scale back the lateral thrust while not the requirement for an outsized and visually obstructing beam. The walls onto that such a roof were placed had to be substantial and were typically supplied with buttresses in line with the principals to contain any lateral thrust which will develop.

TRUSSES

Roofs in truss type developed victimization craft joints and a few steel buirdly, till the latter a part of the eighteenth century once bolts, and even glues, began to be accustomed produce giant truss forms from lighter timber members. Such truss forms typically used softwoods, as distinct from the hardwoods additional often utilized in the shapes antecedently delineated. the massive timber sections in oak notably were changing into terribly scarce and after all terribly costly. while some important advances in span were achieved, victimization the techniques delineated on top of, the domestic roof didn't need terribly giant spans and altered little from the collared coupled roof. so several little terraced homes engineered throughout the eighteenth and nineteenth century needed no principals in the least.

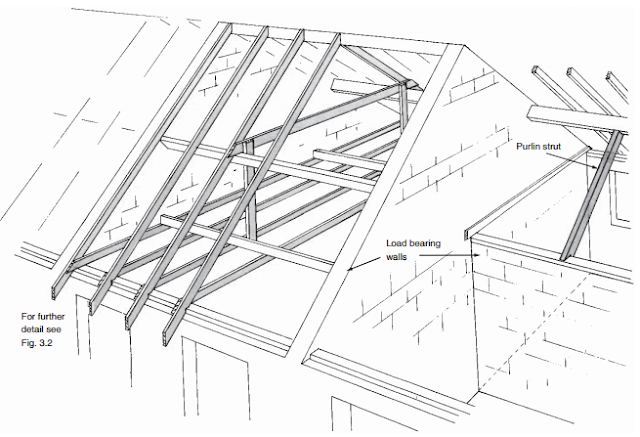

The dividing walls between the homes were shut enough to permit the purlins to rest on these walls, effectively victimization them as principals. Fig: 1.9 illustrates a typical townhouse roof construction.

The larger properties wherever the span of the purlin was too long for one piece of timber, or wherever hip ends were concerned, continued to use the established ways of construction exploitation principals, collars and purlins, however, it absolutely was common apply to omit the principals and to support the purlins of the walls below with posts or struts.

|

| Fig: 1.9 Purlin and common roof |

DESIGN FOR ECONOMY

In 1934 the Timber Development Association (TDA) was shaped, currently referred to as TRADA (Timbervanalysis and Development Association). The Association took up the work already being done at that point by the Royal craft institution and progressed work on timber technology aboard the Forest market research laboratories.

though the Royal craft institution might sound an odd body to have an interest in timber, it should be remembered that a lot of craft of that era, and a few notable ones when like the dipterous insect, used extremely stressed timber structures for the body and wings. Some craft hangars were of timber construction and utilized record-breaking giant span little timber section trusses with locked joints.

After the Second war shortages of materials resulted in a very license being needed for all new building works, creating an economy in the use of preponderant importance. foreign materials like timber were noticeably at a premium and TDA was given the task to search out ways that of economizing on the country’s use of timber.

Quite properly they knew the roof structures of buildings as a high volume user of timber and developed a style for a domestic roof victimization principal trusses created of tiny timber sections connected with bolts and metal connector plates.

The roof used purlins and customary rafters kind of like the systems antecedently mentioned. These trusses became called ‘TDA’ trusses and with some minor modifications square measure still in use these days. It seems that a number of these styles were offered shortly once the Second war, however, was 1st printed as a collection of ordinary style sheets around 1950.

The designs were based on existing truss shapes but were not engineered in the sense that structural calculations were prepared for each design. Load testing on full-size examples of the truss was used to prove their adequacy and from these tests, other designs developed.

STANDARD DESIGN ROOFS

The first designs produced were known as ‘A’ and ‘B’ types, dealing with 40° and 35° pitches respectively. They covered spans up to 30 ft (9 m).

House design fashion changed during the later 1950s and early 1960s, demanding lower roof pitches. 1960 saw the introduction of the TDA type ‘C’ range for pitches between 22° and 30°. Spans were also increased up to 32 ft (10.8 m). Around 1965 the types ‘D’, ‘E’, and ‘F’ ranges were published; these later designs using a slightly different truss member layout went down to 15° pitch and up to 40 ft (12 m) span. Further designs used trusses spaced at 6 ft (1.8 m) centers and had some degree of pitch and span flexibility within specified limitations.

A range of designs for trussed rafters (i.e. each couple tied together at ceiling level) was produced also using bolt and connector joints, but these were designed only to carry felt roof coverings and did not prove as popular as the principal truss designs.

Industrial roofs were not neglected, with principal truss designs using the bolt and connector joint techniques for pitches of 22.5° spacing between 11 and 14 ft (3.35– 4.25 m) and up to 66 ft (20.1 m) span.

Whilst roofs are still constructed using these techniques, the TDA designs are no longer available from TRADA.

BOLT AND CONNECTOR JOINTS

All of the TDA principal and trussed rafter designs used bolts and connectors at joints where previously mortice and tenon, half lap, or straight nailed or pegged joints would have been used. The small timber sections used in the designs of the trusses did not allow the use of conventional carpentry joints and gave an insufficient nailing area for an all nailed assembly.

The connector allows the forces in the joint to be spread over a large area of the connected timber, the bolt holding the timbers in place thus allowing the connector to transmit the load from one truss member to the other.

Fig: 1.10 illustrates the typical single connector joint.

|

| Fig: 1.10 Toothed plate connector joint |